Waterproof coating quality testing standards

防水涂料综合归纳可以分为以下三种:

Waterproof coating synthesis can be divided into the following three types:

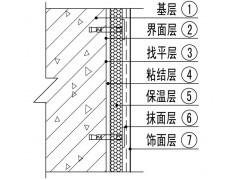

1、有机防水涂料 主要包括合成橡胶类、合成树脂类和橡胶沥青等。有机防水涂料固化成膜后最终是形成柔性防水层,常用于工程的迎水面,这是充分发挥有机防水涂料在一定厚度时有较好的抗渗性,在基面上(特别是在各种复杂表面上)能形成无接缝的完整的防水膜的长处,又能避免涂料与基面粘结力较小的弱点。冬季施工时,水乳型涂料已不适应,应适用反应型涂料,溶剂型涂料也适合冬季施工使用,但由于溶剂挥发会污染环境,故不宜在封闭的地下工程种使用。

1, organic waterproof coating mainly consists of synthetic rubber, synthetic resin and rubber asphalt. Organic waterproofing paint curing film is formed of flexible waterproof layer, commonly used in the engineering of water face, this is to give full play to the organic waterproof coating has good impermeability in certain thickness, the surface ( especially in a variety of complex surface ) can form a waterproof membrane seamless integrated strengths, and to avoid small coatings and surface adhesion. Winter construction, emulsion coating is not suitable, should apply the reactive coating, solvent type coating is suitable for winter construction, but because of the volatile solvent will pollute the environment, so it is not suitable to be used in closed underground engineering.

氯丁橡胶防水涂料、sbs改性沥青防水涂料等聚合物乳液防水涂料属挥发固化型,聚氨脂防水涂料属反应固化型。

Chloroprene rubber waterproof coating, SBS modified asphalt waterproof coating and polymer emulsion waterproof coating of volatile curing, polyurethane waterproof coating is a reaction curing type.

2、聚合物水泥防水涂料 简称js防水涂料,当前国内聚合物水泥防水涂料发展很快,用量日益增多,日本称此类材料为水凝固型涂料,聚合物水泥涂料是以丙烯酸酯等聚合物乳液和水泥为主要原料,加入其他外加剂制得的双组分水性建筑防水涂料,所用原材料不会对环境和人体健康构成危害。具有比一般有机涂料干燥快、弹性模量低、体积收缩小、抗渗性好等优点,国外称之为弹性水泥防水涂料。

2, the polymer cement waterproof paint JS waterproof coating, the current development of domestic polymer cement waterproof paint soon, dosage increasing, Japan said that such materials as moisture-set coating, polymer cement paint is acrylic polymer emulsion and cement as the main raw material, adding other additives prepared two-component waterborne architectural waterproof coating the raw materials used, no harm to the environment and human health. Compared with the general organic paint dry fast, low elastic modulus, shrinkage, permeability good, foreign called the elastic waterproof coating.

防水涂料分为两类:ⅰ型:以聚合物为主的防水涂料

Waterproof coating is divided into two types: type I: waterproof coating with polymer based

ⅱ型:以水泥为主的防水涂料

Type II: waterproof coating to cement as

用途:ⅰ型产品主要用于非长期浸水环境下的建筑防水工程

Application: the product is mainly used for non - type building waterproof engineering long-term immersion environment

ⅱ型产品适用于长期浸水环境下的建筑防水工程

Building waterproof engineering type product is suitable for long-term immersion environment

3、无机防水涂料 主要是水泥类无机活性涂料,包括聚合物改性水泥基防水涂料和水泥基渗透结晶型防水涂料。这是一种以水泥石英砂等为基材,掺入各种活性化学物质配制的一种新型刚性防水材料,它既可作为防水剂直接加入混凝土中,也可作为防水涂层涂刷在混凝土基面上,该材料借助其中的载体不断向混凝土内部渗透,并与混凝土中某种组分形成不溶于水的结晶体充填毛细孔道,大大提高混凝土的密实性和防水性。

3, inorganic waterproof coating is mainly cement inorganic paint, including the polymer modified cement based waterproof paint and cement based permeable crystallization type waterproof coating. This is a kind of cement and quartz sand as a substrate, the incorporation of a new type of rigid waterproofing materials of various active chemical materials, it can be used as a waterproof agent directly into the concrete, but also can be used as waterproof coating painted on the concrete surface, the material with the help of the carrier is not broken penetration into concrete, and the formation of water insoluble crystalline filling the pores and a set of concrete, greatly improve the compactness and waterproof concrete.

防水涂料质量六大检测标准:

Six quality inspection standard waterproof coating:

一、在-25度低温下柔韧度检测:

A, -25 degrees low temperature flexibility test:

在平板玻璃上进行涂蜡,将调制好防水涂料横直各涂刷一道,间隔为二小时,涂膜厚度1.0-1.5毫米,八小时后用指甲感觉干透即从玻璃板上取下,在(25℃±2℃)温度内放置室内7天,然后剪下长二十厘米,宽二厘米的条状,置于-25℃下,将样品放入半小时,用铅笔正反各缠绕一次,无裂缝及断裂者为低温柔韧性检测合格。

To wax on the plate glass, the prepared waterproof paint brushing a horizontal straight the road, interval of two hours, the film thickness of 1.0-1.5 mm, eight hours after the nail feels dry from the glass plate removed, in ( 25± 2 ℃) is placed in the indoor temperature for 7 days, and then cut the long twenty cm, two cm wide strips, at -25℃, put the sample in half an hour, a pencil and the wound, no cracks and fracture for low temperature flexibility detection qualified.

二、断裂延伸率检查:

Check two, fracture extension rate:

在防水施工中,将搅拌好的防水材料,分多次涂刷在已打蜡平整的玻璃板上,涂膜厚度1.0-1.5毫米,放置7天后,在约1%的碱水中浸泡7天,然后在恒温箱中调至50℃土2℃放置二十四小时,做哑铃型拉伸实验,要求延伸保持率达到80%(无处理为200%,如达到标准,则为断裂延伸检查合格,如不合格可增加乳液的用量。

In waterproofing, waterproofing materials will stir well, coating on the glass plate has multiple wax on the smooth, coating thickness of 1.0-1.5 mm, after 7 days, 7 days immersion in about 1% alkaline water, and then to the thermostat at 50 ℃ in soil is 2℃for twenty-four hours, do dumbbell tensile test, request extension keep rate reached 80% ( no treatment was 200%, such as up to standard, for the elongation to inspection, such as unqualified can increase the amount of emulsion.

三、粘结力检查:

Three, bond stress check:

高分子聚合物防水砂浆,可直接成形“8”字模,24小时后出模。放人水中浸泡7天,室内温度25℃±2℃干养护28天,做粘结实验。高分子防水砂浆,灰:水:胶=1:0.11:0.14,高分子防水砂浆为2.3MPa。将高分子防水涂料搅拌制糊状,将和好的涂料涂到两个半“8”字砂浆块上,放置7天做粘结实验,高分子防水涂料配比(高弹),粉:胶=1:1.4;(中弹),粉:胶=1:0.8-1。低分子防水涂料为0.5MPa,大于等于粘结指标为合格。

High polymer waterproof mortar, can be directly formed " 8 " font, 24 hours after the die. Put in the water for 7 days, the indoor temperature of 25± 2 ℃dry curing for 28 days, for bonding experiment. Polymer waterproof mortar, gray water: =1:0.11:0.14 gum, polymer waterproof mortar for 2.3MPa. The polymer waterproof coating mixing paste, will be a good coating to 2.5 " 8" mortar block, place 7 days for bonding experiments, polymer waterproof coating proportion ( high ), powder: gum =1:1.4; ( shot ), powder: adhesive =1:0.8-1. Low molecular waterproof coating is greater than or equal to 0.5MPa, bond index for qualified.

四、不透水性检查:

Four, water impermeability test:

在实验室用专用仪器检测,其方法是将涂料按比例配好,分多次涂刷在已打蜡玻璃板上,涂刷厚度为1.5毫米,静放7天,然后放人烘箱内50℃±2℃烘24小时,取出后放置3小时,做不透水实验,不透水性为0.3MPa。保持30分钟无渗漏及湿印为合格,也可用目测法检验防水效果,方法是将涂料分4—6次涂刷到无纺布上,干透后(约24h)成膜厚度为1.0-1.5毫米,做成鞋盒子形状,再将1%碱水加人盒内,三天后无渗漏为合格。

Special detection equipment used in laboratory, the method is to paint in proportion, multiple populations in wax glass plate, coating thickness of 1.5 mm, and let rest for 7 days, then put in the oven at 50± 2 ℃drying for 24 hours, took place after 3 hours, do not water experiment, don't permeability of 0.3MPa. Hold for 30 minutes without leakage and wet printing for qualified, also uses a visual inspection and waterproof effect, method is to paint in 4 - 6 times coating to the non-woven cloth, dry ( about 24h) film thickness of 1.0-1.5 mm, a shoe box shape, and then the 1% alkaline into the box, after three days without any leakage for qualified.

五、HDPE耐水性检查:将涂料分多次涂刷在水泥块上,成膜厚度1.0-1.5毫米,放置7天,放入1%碱水中浸泡7天,不分层脱皮,不空鼓为合格。

Five, water resistance inspection: paint brush in many cement block, film thickness of 1.0-1.5 mm, placed for 7 days, in 7 days 1% alkali soak in the water, no delamination peeling, no hollowness is qualified.

六、成膜厚度检查:应采用针穿刺法每100平米刺三个点,用尺测量其高度,取其平均值,成膜厚度应大于1.5毫米。穿刺时做好标记、以便修补。

Six, the film thickness should check: thorn three points every 100 square meters by needle puncture method, using a ruler to measure the height, the average values, the film thickness should be more than 1.5 mm. Mark, so do the puncture repair.